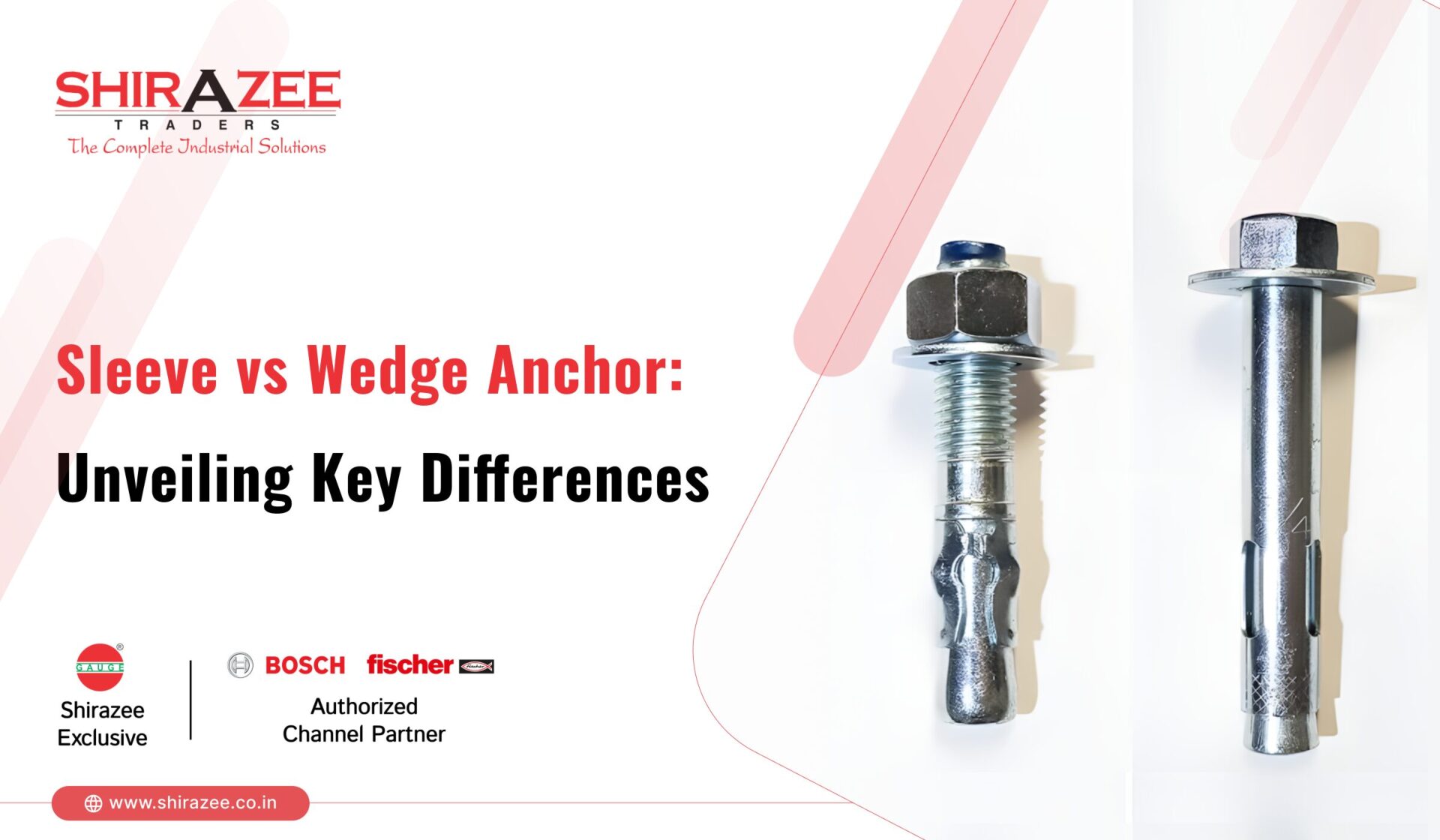

Wedge Anchor

A wedge anchor is a mechanical type expansion anchor that consists of four parts: the threaded anchor body, the expansion clip, a nut, and a washer. It is designed for use in solid concrete only. These anchors provide the highest and most consistent holding values of any mechanical type expansion anchor.

Installing Wedge Anchor into concrete can be accomplished by following the directions below.

-

Assemble the right tools

A hammer drill must be used to create the hole in the concrete

Use a hammer drill set in the hammer and rotation mode. This ensures proper hole dimensions and makes drilling the hole easier.

Not using a hammer drill will make the hole difficult to drill and may decrease the holding value of the anchor once installed.

-

Determine the sizes

Determine the minimum length of wedge anchor to use by adding the thickness of the material to be fastened to the minimum embedment for the diameter of the anchor to be installed with space for the nut and washer.

These anchors can be installed at deeper embedment than the minimum embedment depth. In most cases, this will provide better holding values.

Use a bit that is the same diameter as the anchor being installed.

Use an ANSI standard carbide-tipped masonry bit, and chuck it into the hammer drill.

Use ANSI standard bits to ensure proper hole tolerance between the hole diameter and anchor diameter.

Hole tolerance is critical to ensure minimum holding values.

-

Drill the hole

Drill a hole that is slightly deeper (a minimum of 1/2”) than the expected embedment depth.

Make sure that the minimum embedment depth for the diameter of the anchor is met. The minimum depth of embedment after the anchor is set is as follows:

Minimum Embedment Depth by Diameter of Wedge Anchor

Wedge Anchor Diameter

Minimum Embedment Depth

1/4” 1-1/8”

5/16” 1-1/4”

3/8” 1-1/2”

1/2” 2-1/4”

5/8” 2-3/4”

3/4” 3-1/4”

7/8” 3-7/8”

1” 4-1/2”

1-1/4” 5-1/2”

-

Check the depth

Be sure the depth of the hole is correct. Set the depth gauge on the hammer drill or place tape on the bit at the required depth.

Make sure that when placing the tape on the bit or setting the depth gauge that the bit is in the retracted position. The retracted position is when the bit is at its most inward position in the chuck.

-

Clean the hole

Clean the hole of all dust and debris to help ensure proper holding values once the anchor is installed. Clean the hole by using a wire brush, vacuum, or compressed air.

Use a wire brush to clean the hole, and then vacuum the hole. Repeat this a few times, and the hole will be clean and ready for installation.

-

Install the wedge

Each box of anchors comes with the correct number and size of nuts and washers.

Take one washer and place it over the threaded end of the anchor body.

Then take one nut and thread it clockwise onto the anchor body until the top of the nut is flush with the top of the anchor body. This protects the threads of the anchor during installation.

Install the anchor through a hole in the fixture, or install directly into the concrete, and then place the fixture over the anchor.

Through Fixture – If the anchor is going to be installed while the fixture is in place, make sure that the hole in the fixture is slightly larger than the designated diameter of the anchor (see chart below). Insert the anchor, clipped end first, through the hole in the fixture and into the in the concrete. With a hammer, strike the nutted end of the anchor until the washer and nut are tight against the surface of the concrete. Make sure that the anchor is embedded at least to the minimum embedment depth, (see chart above).

Wedge Anchor Diameter

Minimum Fixture Hole

1/4” 5/16”

5/16” 3/8”

3/8” 7/16”

1/2” 9/16”

5/8” 3/4”

3/4” 5/8”

7/8” 1”

1” 1-1/8

1-1/4” 1-3/8”

Direct into Concrete – Insert the anchor directly into the predrilled hole in the concrete with the clipped end going first. Strike the nutted end of the anchor with a hammer until the anchor is embedded into the concrete the required distance, see the minimum embedment chart above. Make sure that a minimum of three to five threads are below the surface of the concrete and there are enough threads above the surface to accommodate the thickness of the material being fastened and space for the nut and washer.

To set the anchor in the concrete, turn the nut clockwise with your fingers until tight. Then use a wrench to turn the nut clockwise three to five full turns, or until the specified torque value is reached for the diameter of the anchor being installed. Over torquing the anchor may cause the anchor to spin in the hole and the holding values will be compromised.

Wedge Anchor Installation Torque

Diameter

Torque Ft/lbs

1/4” 4

3/8” 25

1/2” 55

5/8” 90

3/4” 110

7/8” 250

1” 300