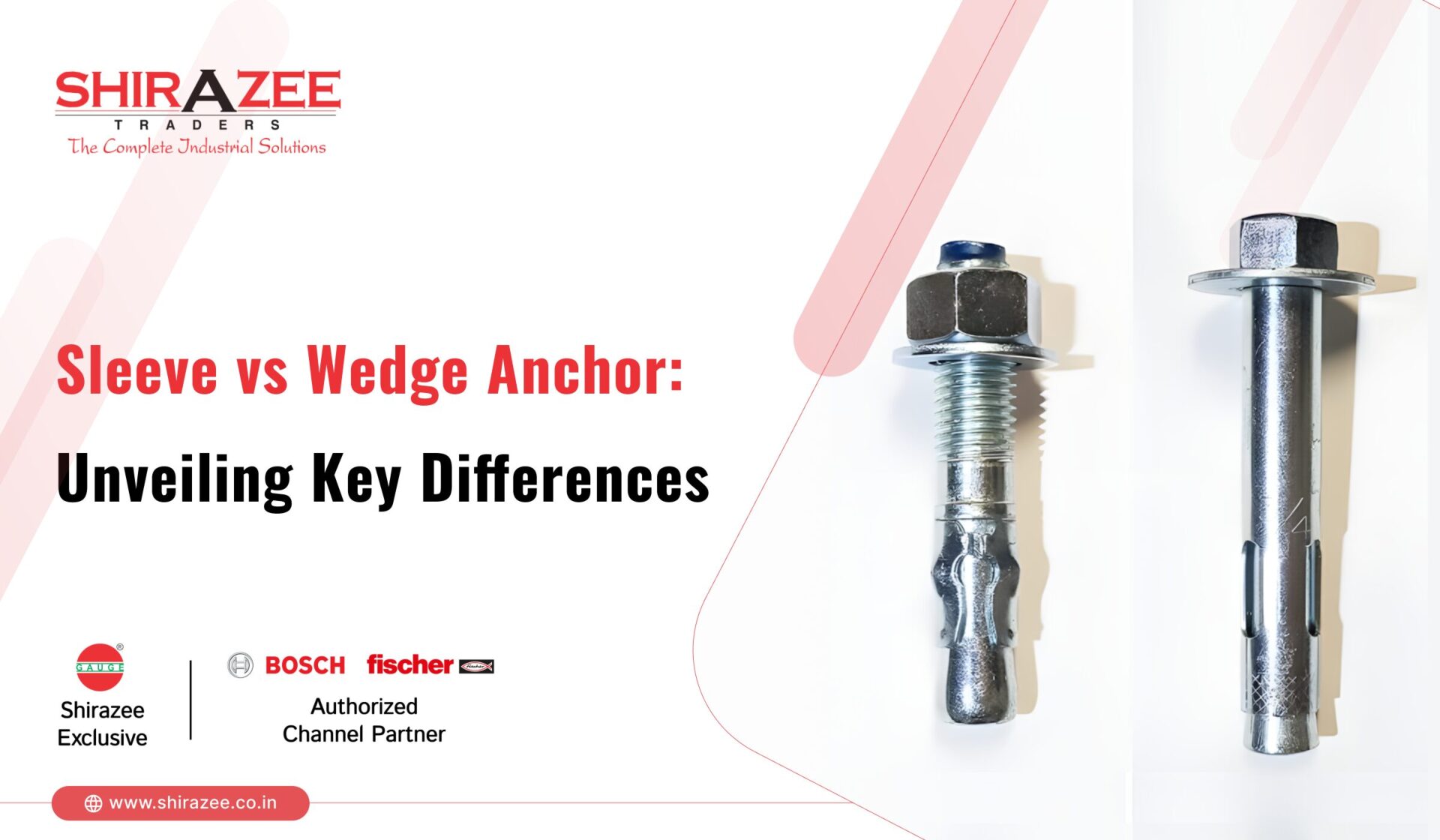

When it comes to anchoring solutions for concrete applications, both sleeve anchors and wedge anchors play a pivotal role. However, choosing the right anchor depends on various factors such as the nature of the load, environmental conditions, and the concrete’s condition. In this blog, we will explore the distinct features, advantages, and disadvantages of sleeve anchors and wedge anchors, and help you understand their key differences to make an informed decision.

Introduction to Sleeve Anchors and Wedge Anchors

- Sleeve Anchors: Sleeve anchors are versatile fasteners used in a variety of materials including concrete, brick, and block. They consist of a split expansion sleeve with an expander nut at the end. When the nut is tightened, the sleeve expands to press against the walls of the pre-drilled hole in the base material, securing the anchor in place.

- Wedge Anchors: Wedge anchors, on the other hand, are designed exclusively for use in concrete. As the nut is tightened, the tapered end is pulled into the expansion clip, wedging it outward to lock the anchor firmly into the concrete.

Types of Wedge Anchors

Wedge anchors can be further classified into two categories:- Mild steel wedge anchors and Stainless steel wedge anchors.

- Mild steel wedge anchors are essential hardware tools for construction and renovation projects, known for their robust performance in fastening fixtures into solid concrete. These anchors are made from mild steel, which offers a blend of flexibility and strength, making them suitable for applications where dynamic loads are not a primary concern. As a cost-effective solution, mild steel wedge anchors are widely used in non-corrosive environments or where temporary installations are required. Despite being less resistant to environmental elements than stainless steel, their affordability and efficiency make them popular among contractors who need reliable anchoring without the extra expense for high-corrosive conditions.

- For environments that demand the highest level of durability and resistance to corrosion, stainless steel wedge anchors present an ideal choice. These anchors are crafted from high-grade stainless steel, which provides exceptional resistance to rust and degradation, making them perfect for outdoor applications and in settings exposed to chemical agents or saline water. Stainless steel wedge anchors are indispensable hardware tools in projects requiring long-term strength and stability, such as in marine construction, food processing plants, and coastal buildings. Their superior strength and anticorrosive properties ensure that they maintain holding power and integrity over years, despite harsh conditions.

Features, Advantages & Disadvantages

Sleeve Anchors:

- Versatility: Sleeve anchors can be used in a variety of base materials.

- Removability: They can be fully removed, leaving a clean hole which is beneficial in temporary installations.

Advantages of Sleeve Anchors

- Suitable for lighter loads.

- Provides consistent holding values in a variety of base materials.

- Easy to install and remove which makes them ideal for projects requiring adjustability or temporary fastenings.

Wedge Anchors:

- High Strength: Wedge anchors provide a permanent and strong hold, ideal for structural applications.

- Durability: They are often made from stainless steel or zinc-plated steel to resist corrosion.

- Load Capacity: Designed to handle heavier loads compared to many other types of concrete anchors.

Advantages of Wedge Anchors

- Exceptional strength and reliability in concrete.

- Permanent installation ensures long-term support.

- Suitable for critical, high-stress applications.

Disadvantages

Sleeve Anchors:

- Not suitable for heavy loads.

- Expansion can cause stress in fragile materials, potentially leading to cracking.

Wedge Anchors:

- Irremovable; once installed, they are difficult to remove without damaging the concrete.

- Limited to concrete; not suitable for other base materials.

Difference between Sleeve Anchors and Wedge Anchors

While both anchors are used for securing fixtures into concrete, their applications differ significantly based on their design and mechanical properties. Sleeve anchors offer flexibility and ease of removal which makes them suitable for non-structural applications in a variety of materials. Wedge anchors, on the other hand, are suitable for high-load, permanent applications in concrete environments. Wedge anchors deliver higher pullout resistance, making them ideal for supporting beams, columns, heavy machinery, etc. Sleeve anchors are preferable for lighter, temporary installations like mounting frames, electrical boxes, and railings.

Conclusion

Choosing between sleeve and wedge anchors largely depends on the specific requirements of your project. For heavy-duty, permanent applications in concrete, wedge anchors are undoubtedly the superior choice. However, if you need an anchor that provides versatility and easy adjustability or removal, sleeve anchors are more appropriate. Before selecting an anchor, consider factors such as load requirements, base material, and environmental conditions. Understanding the unique features and limitations of each anchor type will help you make a decision that ensures safety, efficiency, and structural integrity in your anchoring projects. Always consult with a structural engineer or a professional installer when in doubt to ensure optimal performance and safety of your installations.