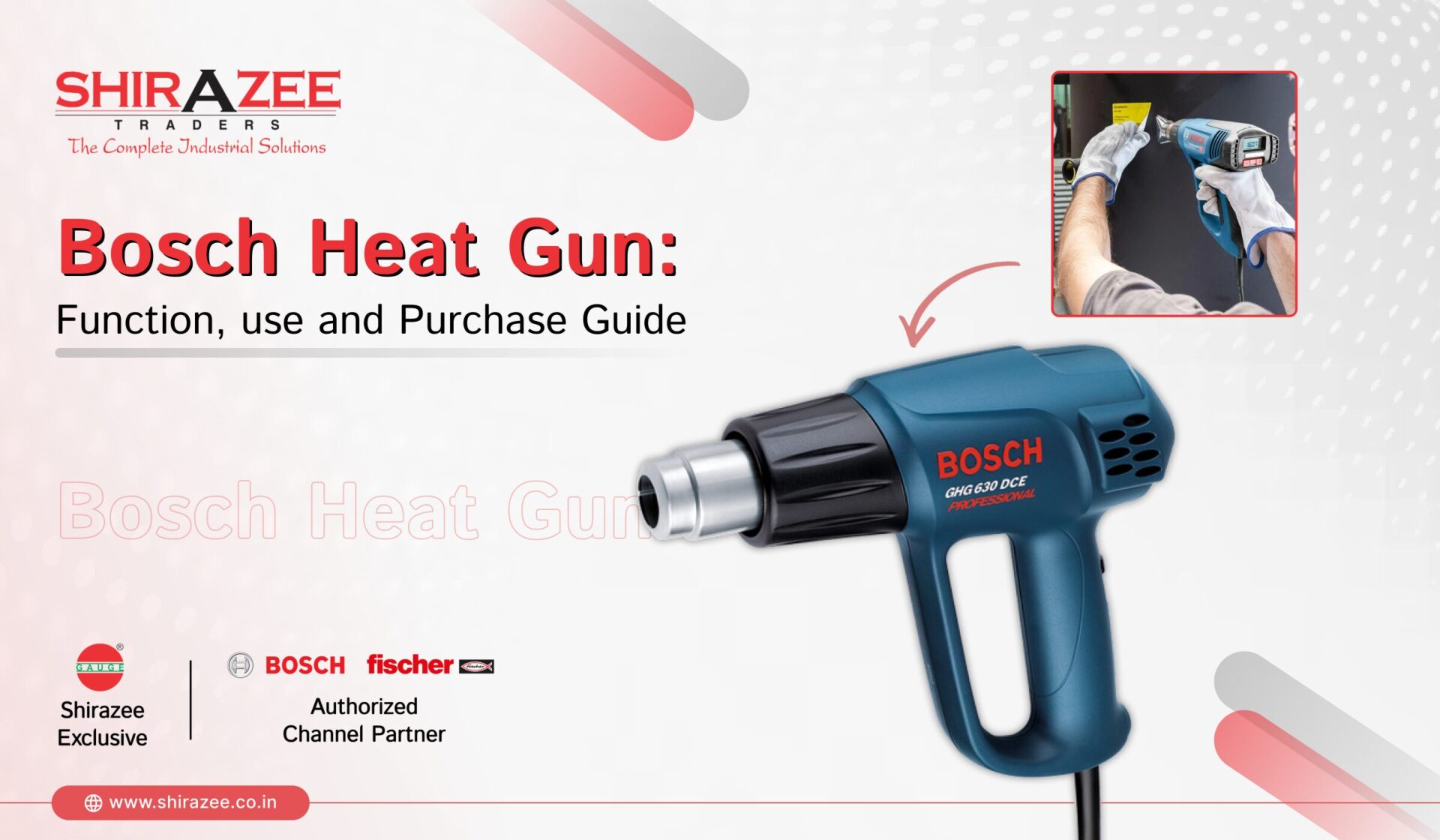

There are not many gadgets that are as unique as the Bosch heat gun in the wide world of hardware tools. This portable wonder, which is highly regarded for its adaptability, dependability, and wide range of uses, has turned into a vital tool for both professional tradespeople and DIY enthusiasts. We take you on a journey through the complexities of the Bosch heat gun in this in-depth blog, covering its many uses, useful tips, and important factors to take into account before making a purchase.

Knowing what the Bosch heat gun can do is essential, whether you’re trying to remove paint, shrink-wrap items, thaw frozen pipes, or do any number of other tasks. To give you the knowledge you need to use this potent tool confidently and skillfully, let’s delve into the depths of its functionality, usage, and purchasing details.

Functionality of the Bosch Heat Gun

Fundamentally, the Bosch heat gun is a portable gadget designed to generate and disperse a concentrated stream of heated air. The heat gun is an extremely adaptable tool that can be used for a wide variety of tasks because of its ability to precisely adjust the temperature and intensity of the airflow that is produced when an electric current is passed through a heating element.

The Bosch heat gun is particularly good in the following areas

1. Paint Stripping: Using high temperatures, the heat gun easily softens and removes paint layers from a variety of surfaces, such as plastic, metal, and wood, making renovation and refurbishment projects more efficient.

2. Shrink Wrapping: Using a heat gun to apply a regulated stream of hot air to shrink wrap film allows users to firmly seal and fasten items, providing a practical answer to packaging and safeguarding requirements.

3. Defrosting Frozen Pipes: Pipes can freeze during bad weather, which can lead to blockages and possible damage. The Bosch heat gun quickly thaws frozen pipes, saving money on repairs by using its quick heating capabilities.

4. Welding and Soldering: The heat gun can be used in specific applications to solder metal components or weld plastic materials, offering a convenient and adaptable substitute for conventional methods.

5. Drying and Defrosting: The heat gun offers a quick and effective way to remove moisture and thaw, from accelerating paint drying processes to defrosting locks and mechanisms.

Utilization Techniques for the Bosch Heat Gun

Following recommended usage guidelines is essential if you want to make the most of the Bosch heat gun and get the best results in a variety of applications. The following are some crucial pointers for using heat guns effectively:

1. Put Safety First: Prioritize safety by ensuring that all necessary precautions are taken before using the heat gun. These precautions include wearing goggles, protective gloves, and appropriate clothing to reduce the risk of burns and injuries.

2. Temperature Adjustment: Learn how to use the heat gun’s temperature control settings and determine what heat levels are suitable for each particular task. Start at lower temperatures and raise them gradually as needed to avoid distorting the material or causing surface damage.

3. Maintain Distance: To avoid burning, warping, or scorching, keep the heat gun’s nozzle a constant distance away from the target surface, usually between two and four inches. To minimize localized overheating and ensure uniform heat distribution, it is recommended to move the heat gun continuously.

4. Sufficient Ventilation: Make sure there is sufficient ventilation when performing tasks like paint stripping in order to disperse fumes and airborne particles, protecting respiratory health and enhancing environmental safety.

5. Exercise Patience: Give the heat gun enough time to reach its operating temperature before starting any work, and be patient when applying it to gradually achieve the desired results.

6. Experiment and Improve: Before starting large projects, familiarize yourself with the heat gun’s capabilities by experimenting on scrap pieces with different materials, temperatures, and techniques. Iterative methods enable optimal performance and skill refinement.

Purchase Guide for the Bosch Heat Gun

When considering the purchase of a Bosch heat gun, it is essential to use a thoughtful and well-informed approach in order to select a model that best suits your needs and preferences. Take into account the following elements to help you make an informed purchase choice:

1. Power and Performance: Determine whether the heat gun is appropriate for the intended uses by assessing its power rating and temperature range. More precision and versatility are available with models that have temperature and speed settings that can be adjusted.

2. Durability and Construction: To ensure longevity and dependability, give preference to heat guns made of sturdy, premium materials that can withstand harsh use and environmental conditions.

3. Design and Comfort: Evaluate the heat gun’s proper grip, balance, weight distribution, and design to see if it is comfortable to use for extended periods of time. This will reduce user fatigue and increase output.

4. Compatibility and Accessories: Check for compatibility with a wide range of attachments and accessories, like nozzles, scrapers, and reflectors, which enhance functionality and increase the range of applications.

5. Warranty and Reputation of the Brand: Select reliable brands like Bosch that are well-known for producing high-quality tools. Examine warranty details and client testimonials to determine dependability, client happiness, and after-sale assistance.

6. Proposition of Value: The overall value proposition and return on investment of the heat gun are determined by balancing cost considerations with desired features, performance attributes, and long-term benefits.

Conclusion

Finally, the Bosch heat gun proves to be an effective partner in the hardware tools collection, providing unmatched performance, adaptability, and usefulness in a wide range of applications. Its extensive functionality enables users to take on a variety of tasks with assurance and effectiveness, from shrink wrapping and paint removal to pipe thawing and more. Through adherence to appropriate utilization techniques and thoughtful considerations when making purchases, people can fully utilize the Bosch heat gun and realize substantial benefits in terms of project outcomes, cost savings, and productivity. For experienced professionals or do-it-yourselfers, alike, the Bosch heat gun is a necessary tool for achieving superior quality in design and engineering.